IN IVD SYSTEMS

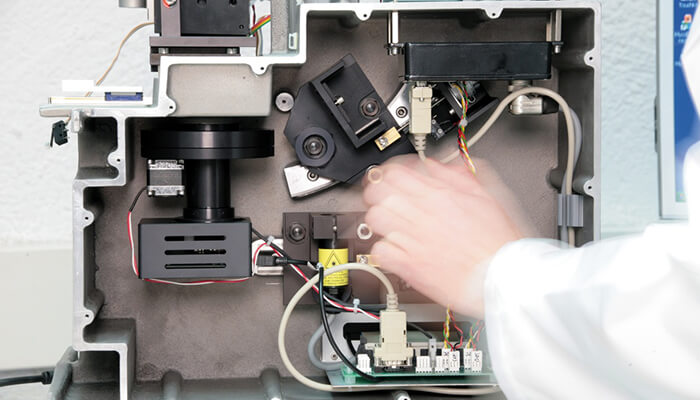

Design and

Development

We can help you get your new IVD, medical, or life science device to the market fast at targeted cost.

Manufacturing and

After-Sales Service

We can fulfill your product needs in high and low volume and build and service your products globally at scale and cost.

Hematology

Solutions

We design, develop, and manufacture hematology systems (low and mid-volume markets) for OEM partners.

Innovation

Develop and build cutting-edge instruments and be on the forefront of shaping the medical device market.

Inclusiveness

Join a dynamic, diverse, and global team with accessible executives who encourage employee engagement.

Impact

Help deliver critical, life-changing technologies to improve and save lives around the globe.

Investment

Our employees enjoy a competitive salary, benefits package (e.g., paid holidays, retirement plan), and company events.

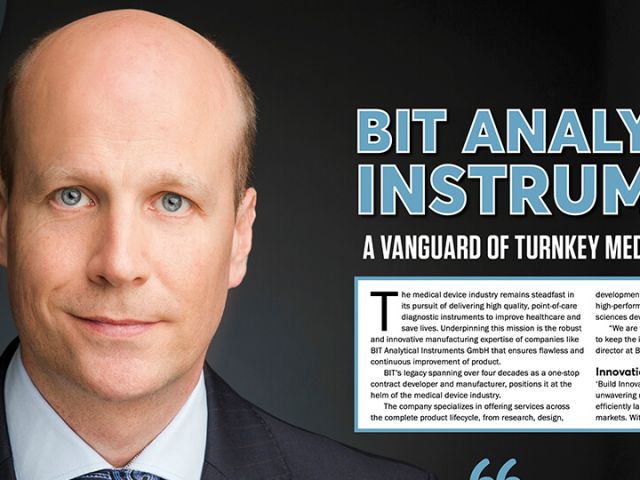

We are honored to be included in the list of “The Most Trusted IVD Medical Device Companies 2024” by The Lifesciences Magazine. Read the full interview here.

Wir freuen uns sehr, dass das Wirtschaftsforum in seiner aktuellen Ausgabe über unsere Auszeichnung, die wir von dem Magazin MedTech Outlook erhalten haben, berichtet.

We are honored to be included in the Top 10 In Vitro Diagnostics Solution Providers 2023 by the renowned MEDTECH OUTLOOK publication. Read the full interview here.